Productivity increase

No need to wait, there is no need to "heat" the lamps. Instant On! More power means less time exposing. Without waiting times, faster changes in exposure are achieved. With these factors, production per day can be increased.

Environment friendly

UV-A solid state LED technology offer better than 50 percent lower CO₂ emissions. UV-A LED lamps generate no ozone and offer the promise of eliminating toxic mercury in an entire category of industrial processes.

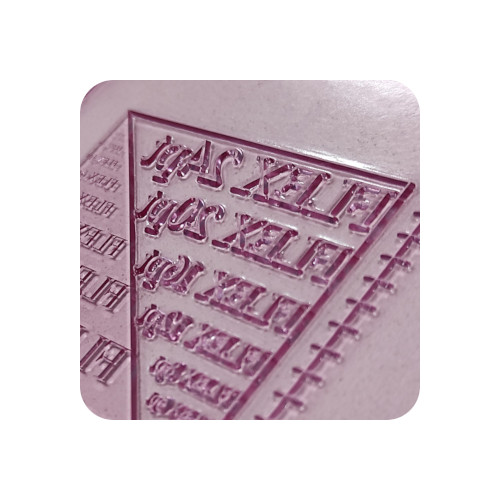

Photopolymer Printing Plates

Go above and beyond

Summit Graphics plate manufacturer offer a full lineup of photopolymer products. Our portfolio of flexographic printing plate solutions consists of photopolymer analog and digital.

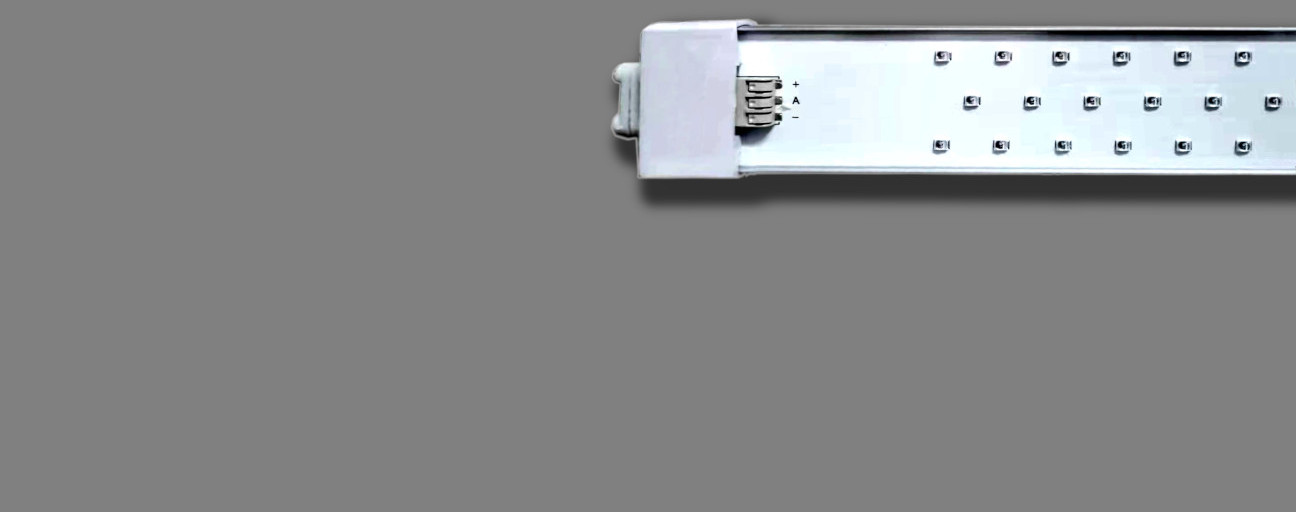

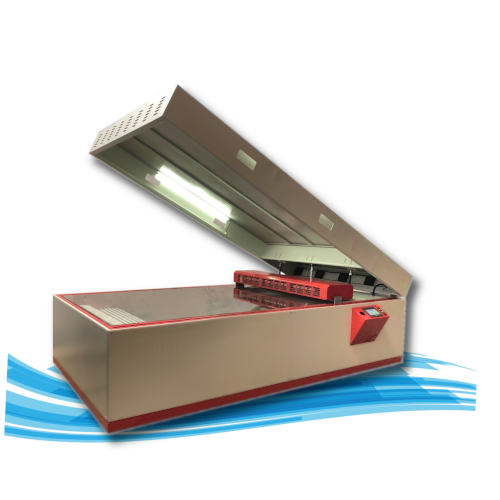

LED UV Exposure Unit

Be cutting edge

Our flagship exposure units equipment: The Pure UVA LED. These machines are specially designed for digital polymers. They have a modern control system that is executed by a PLC with a touch screen interface for the operator, which makes handling simple and intuitive. With a power 20 times higher than conventional tube UV systems, the UVA LED Scanner technology makes polymer exposure uniform and highly repeatable.

Hand in hand with all these amazing features, The UVA LED Scanner exposure equipment provide a unique advantage: The formation of flat dots using standard digital polymers.

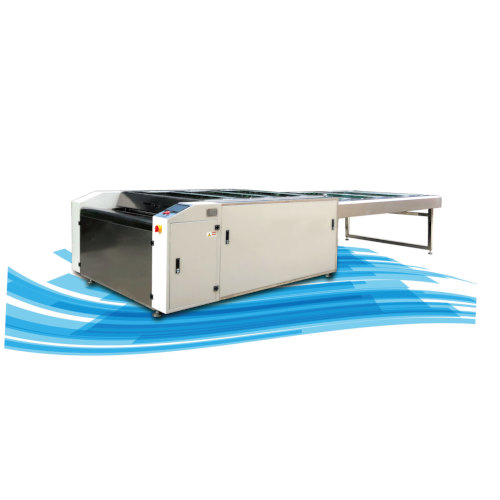

Digital Flexo Processors

Find the best option

Our top of the line washing machine: The LPD Series polymer washing unit is specially designed for digital polymers. In order to improve the final quality of the polymer dots, the movement of the main washing brush was designed not to transmit vibrations.

The LPD polymer processor is equipped with temperature control and automatic solvent regeneration, it also contains a solvent vapor extractor and an outlet table with hot air recirculation.

For a dynamic management of the equipment, it is controlled by a PLC with a touch screen interface for the operator.

Flexo Post-Processing Units

Discover new posibilities

Our PostFPD series drying and processing (Anti-Tack) ovens are specially designed for digital and conventional polymers. Its control panel is simple and intuitive.

These equipments have two drying oven trays with a structure designed to maintain uniform temperatures.

With its uniform light system and temperature control with tolerance +/- 5ºC, it guarantees high repeatability in polymers.