SUMMIT CLOSED LOOP

-

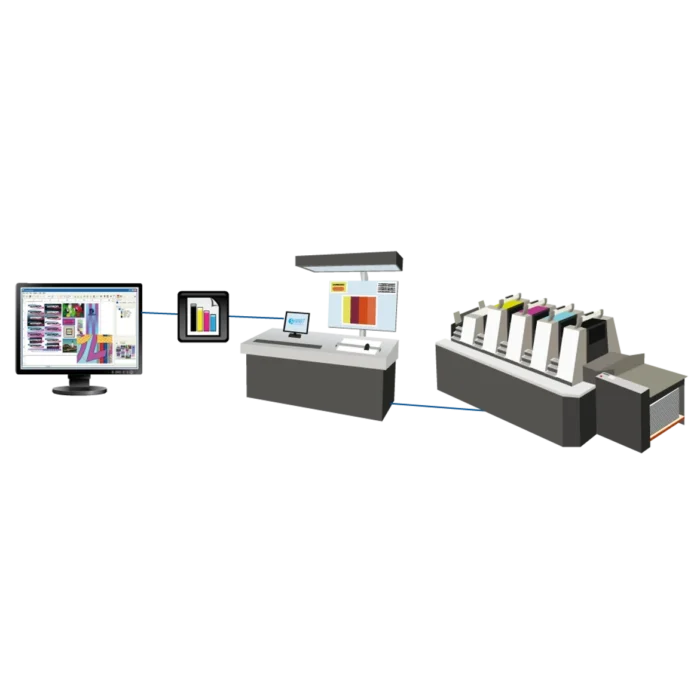

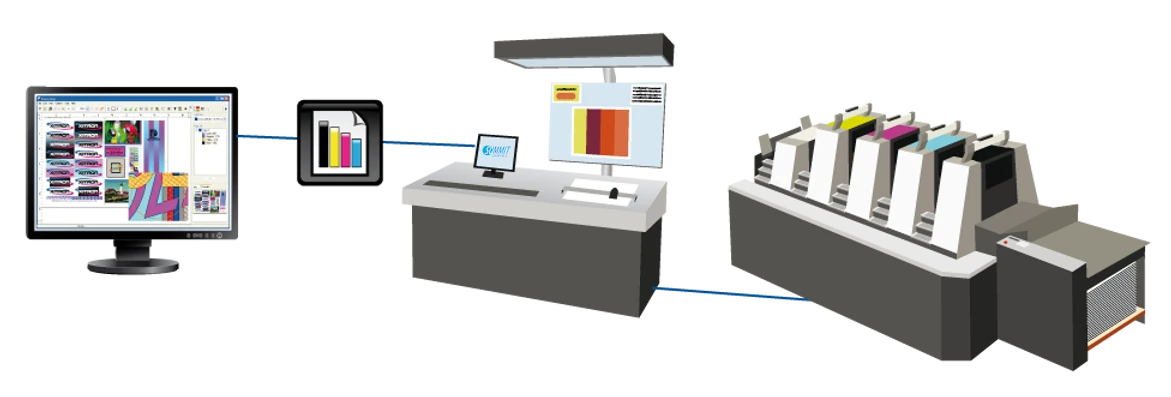

What is Closed loop: Closed loop color is essentially an on-press feedback system that scans and measures the color bar on the moving paper (web or sheetfed)– while the press is in operation — and then feeds this information back to the press console to make automatic adjustments to achieve Targets.Why is this important? Hitting offset lithographic color targets isn’t always fast or easy. The manual process of measuring color bars and making ink key adjustments takes time and opens the door to operator error. Meanwhile, the press is running (and wasting) paper and ink. To achieve accurate and repeatable color, printers need to convert their printing operation to an efficient manufacturing process and drive efficiencies in all phases of their operation.

Closed-loop automates the process by capturing spectral data directly from the press sheet and automatically updating the ink keys. It cuts down on paper and ink expenses that accumulate when you’re not getting up to color quickly, makes short runs more profitable, and minimizes operator intervention. It’s so much faster and more accurate than a traditional workflow that it pays for itself almost immediately.

-

Brings new increased quality to printers.

-

Helps reduce costs and increase productivity.

-

Fast return on investment.

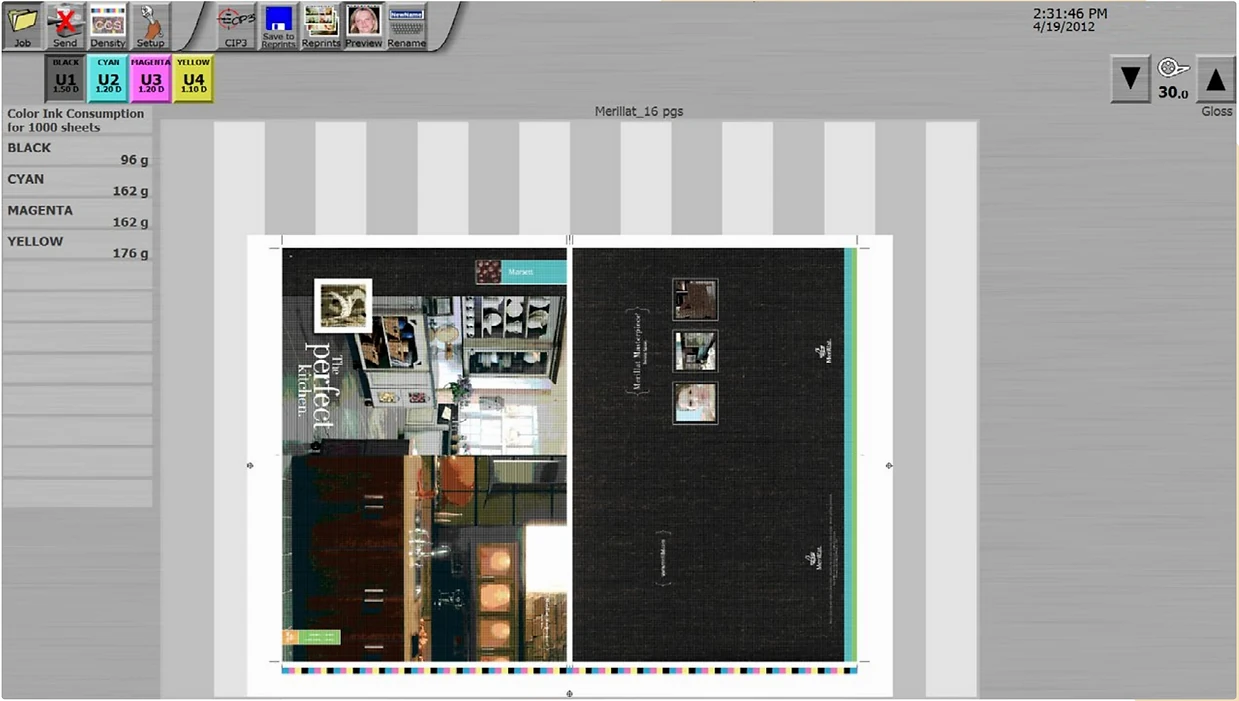

- Press operators get a visual preview of each job right at their console, making it easy to verify the correct job is prepped and ready.

- Accepts CIP3/4 (.ppf) and TIFF files. PDF input options are also available.

- Summit Closed Loop stores the final press settings for each press run, reducing make-ready for repeat jobs by as much as 90%.

- Store profiles for up to unlimited different papers stocks to quickly ensure accurate reproduction based on absorption and reflective response.

- Summit Closed Loop intelligently learns from each job run based on the changes provided by the press operator. As more jobs are run, the system utilizes this information to make adjustments that more closely match print requirements.

- Summit Closed Loop may be equipped with an optional low-resolution RIP that accepts PDF files to quickly convert job files to TIFF or CIP3 data. This option is available when CIP3 or TIFF output from the prepress workflow is an option.

- Sheet press with floppy drive

- Sheet press with floppy drive

- Sheet presses 2007 and earlier with CPC 1.02 or 1.04

- Web presses 2007 and earlier with CPC 1.02 or 1.04

- Sheet presses with CP 2000 with flash card reader

- Web presses with CP2000 with flash card reader

- Presses with chip card reader

- Sheet and web presses with floppy drive

- Presses with 1.4 MB diskette drive using COL format

- Presses with 1.4 MB diskette drive using GRO format

- Sheet press with BOTH a magnetic tape drive and a diskette drive

- Web press with BOTH a magnetic tape drive and a diskette drive

- 54IVP with card reader

- Sheet press with floppy drive

Summit Closed Loop Preview

Summit Closed Loop Levels

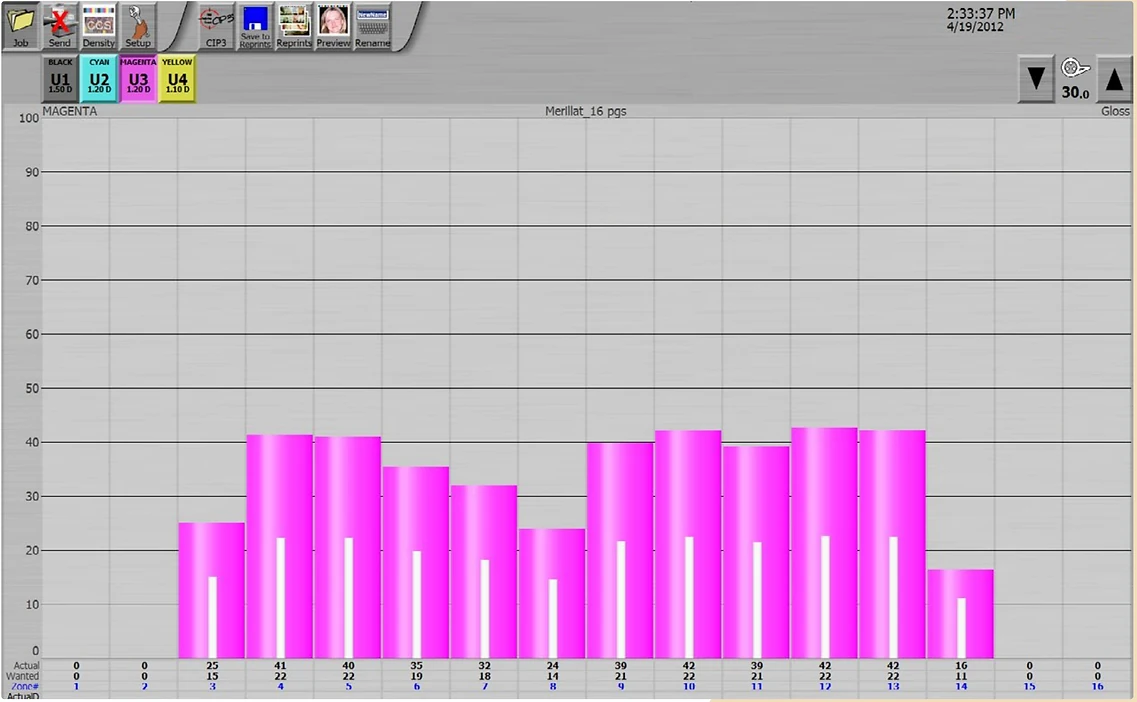

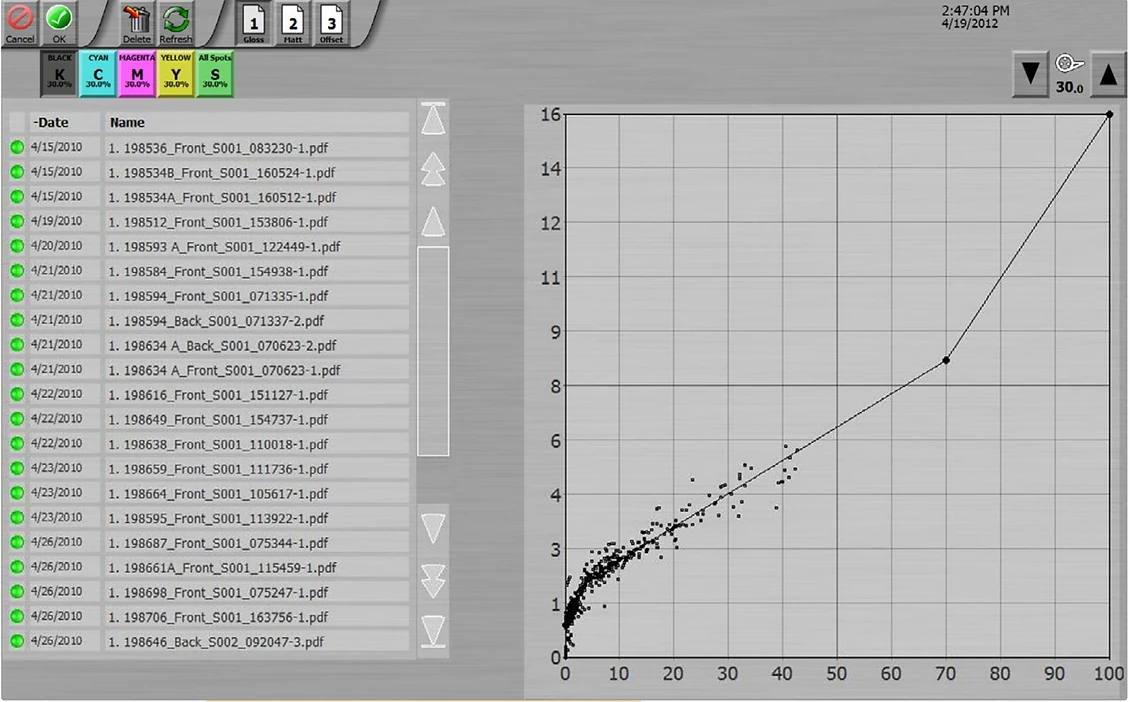

Summit Closed Loop Graph

SUMMIT CLOSED LOOP

-

SUMMIT CLOSED LOOP option that incorporates an automated spectrophotometer (purchased separately) is available.

Simple to set up, understand, and use, Summit Ink Preset can be integrated with your press console and operate in less than one day.

SUMMIT CLOSED LOOP COLOR CONTROL SYSTEM

-

In today´s competitive business environment there is an ever increasing need for more productivity, offering a rapid turnaround, while maintaining the highest levels of color consistency. Summit Closed Loop expands the benefits of CIP3 compatibility (Summit Ink Preset) and advanced closed-loop color management. Summit Closed Loop works with scanning densitometers and spectrophotometers (purchased separately). When scans are executed, the scan data is automatically sent to Summit Closed Loop where it displays both the measured values and the necessary key movements to correct the color. This data is then transferred directly to the press console. The press console automatically adjusts the ink keys to enable the required colors to be achieved.

BENEFITS

FEATURES

Job Preview

CIP Compatible

Job Archiving

Paper Stock Curve Storage

System Learning

Optional RIP Add-On

SUMMIT CLOSED LOOP Supported Press Consoles

Summit Ink Preset combines the Summit software with a hardware connection to communicate ink key data directly with the console.

Adast

Akiyama

Heidelberg

Manroland

Mitsubishi

KBA

Komori

Shinohara

Sakurai

Do you want more information?

Please contact us if you have any questions, comments or quote request. We will gladly answer your questions.

Use the form below to contact us and we will get in touch as soon as possible.

Once your question has been submitted, a sales representative will answer your question or send you a quote.