Increase the quality of your photo-polymers. Obtain greater fluidity in production. Modernize your production processes.

Increase your Production Possibilities Frontiers

Win or Win

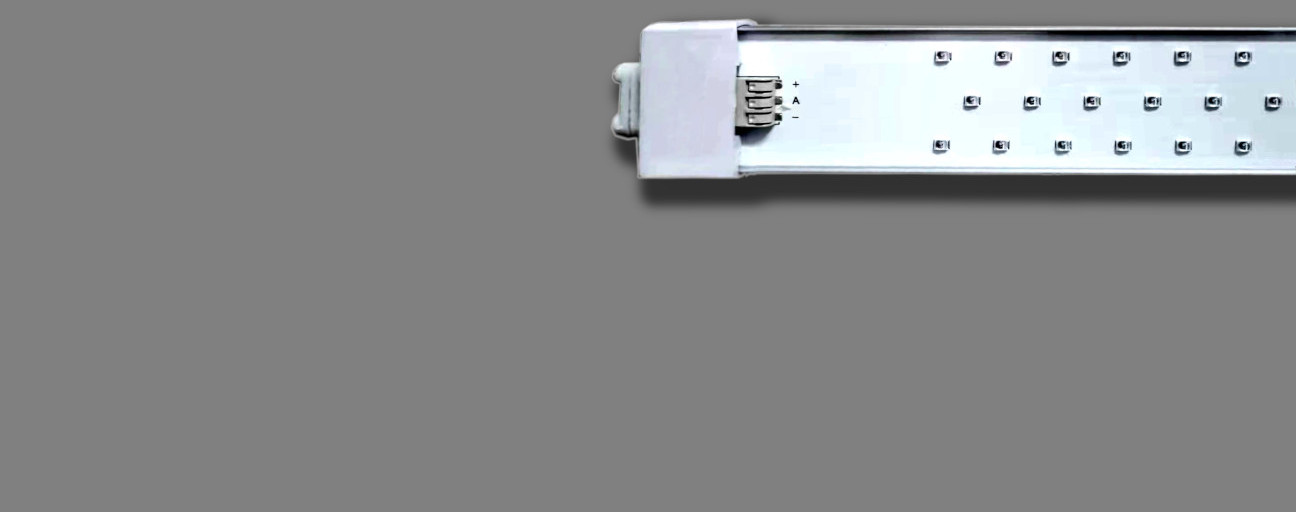

LED UV exposure systems operate at much cooler temperatures than traditional mercury arc light tube UV curing, allowing polymers to be processed more safely and without warping. UV LED curing offers better dot reproduction, higher stability. LED UV light has a defined wave spectrum, suitable for flexo polymers, unlike traditional mercury arc light tube UV where the light is emitted in a broad light spectrum.

UV LED technology offers better uniformity across the exposure width. Additionally, UV LED output degrades at a much slower rate over its lifetime compared to mercury arc light tube lamps which degrade 15-25% after only 1,000 hours of operation. Therefore, UV LED exposure provides a more reliable and stable process that results in more consistent polymer results.

These two great characteristics translate into a notable increase in production, since being able to process polymers more reliably, stable, with greater safety and without deforming them, implies less damage to the material and more consistent polymers are obtained. As a consequence of these results, a greater fluidity is created in the production plant, which increases productivity.